High-Density Polyethylene (HDPE) sheets have become an essential material in a wide range of industries due to their impressive strength, durability, and resistance to various environmental factors. These sheets, made from a highly crystalline form of polyethylene, offer excellent performance for demanding applications in construction, packaging, agriculture, and more. This article provides a comprehensive guide to understanding Hdpe sheet manufacturers in Gujarat, their applications, advantages, and how to source them from trusted suppliers and manufacturers, especially in Gujarat and Ahmedabad.

What Are HDPE Sheets?

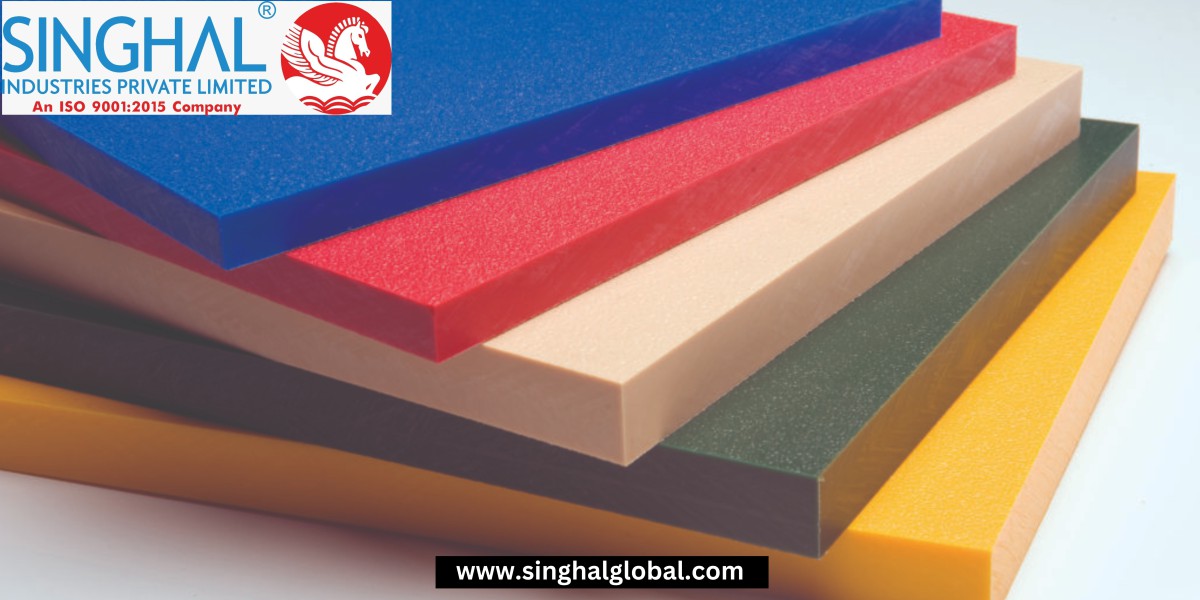

HDPE (High-Density Polyethylene) sheets are a form of plastic material that is highly rigid, durable, and resistant to chemical exposure and impact. HDPE is known for its high tensile strength and low moisture absorption, making it ideal for applications that require tough and long-lasting materials. HDPE sheets are produced through the polymerization of ethylene, typically through a process called extrusion, which involves melting the polymer and shaping it into sheets of varying thicknesses, widths, and colors.

Due to their versatility and high performance, HDPE sheets are used across a range of industries, including manufacturing, construction, agriculture, and transportation.

Key Properties of HDPE Sheets

1. Durability

HDPE sheets are known for their excellent resistance to wear and tear. Their tough and rigid nature makes them highly durable even under challenging conditions. This durability allows them to withstand heavy loads and environmental factors like UV radiation, moisture, and extreme temperatures.

2. Chemical Resistance

One of the most significant advantages of HDPE sheets is their resistance to chemicals. They are not easily affected by acids, bases, alcohols, or other harsh chemicals, making them a preferred choice in industries like chemical processing, agriculture, and wastewater treatment.

3. High Strength-to-Weight Ratio

HDPE sheets offer a high strength-to-weight ratio, which means they provide excellent strength while remaining relatively lightweight. This property makes them ideal for applications that require both toughness and ease of handling, such as in the transportation of materials or packaging.

4. Low Friction

Due to the smooth surface of HDPE sheets, they exhibit low friction properties, making them suitable for use in sliding applications. This feature is especially beneficial in conveyor systems, chutes, and other equipment requiring low friction surfaces to improve operational efficiency.

5. Water Resistance

HDPE sheets are highly resistant to water, making them suitable for use in marine environments, as well as in applications where water resistance is crucial, such as in the construction of water tanks, pipes, and liners for landfills.

6. Recyclability

HDPE sheets are fully recyclable, which makes them an environmentally friendly choice for businesses looking to reduce their environmental footprint. Recycled Hdpe sheet suppliers in Ahmedabad can be reused in manufacturing, helping conserve resources and reduce waste.

Applications of HDPE Sheets

1. Packaging Industry

HDPE sheets are commonly used in the packaging industry due to their durability and resistance to moisture. These sheets are utilized to create packaging materials, including trays, containers, and bags. HDPE is ideal for packaging products that need to be protected from water or chemicals.

2. Construction and Civil Engineering

In construction, HDPE sheets are used for various purposes, including vapor barriers, insulation materials, and protective liners for foundations. The material is also employed in the construction of underground storage tanks, drainage systems, and pipelines, where its resistance to corrosion is highly beneficial.

3. Agriculture

HDPE sheets are used in agriculture for the construction of greenhouse films, irrigation systems, and protective covers. The material's resistance to UV radiation and chemicals makes it ideal for outdoor agricultural applications. Additionally, HDPE is used for agricultural liners and weed barriers, offering a durable solution to soil erosion and unwanted plant growth.

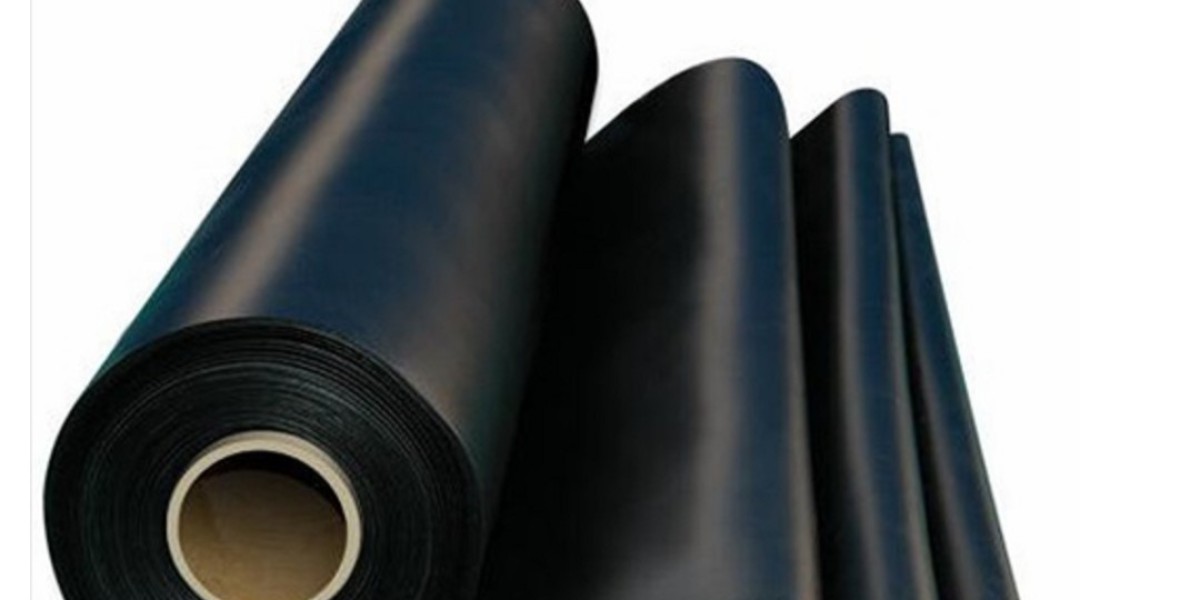

4. Waste Management

Due to their chemical resistance and water resistance, HDPE sheets are often used in waste management applications, including landfill liners and waste containment barriers. These sheets help prevent contamination of soil and groundwater by providing an impermeable barrier between waste and the environment.

5. Marine Applications

HDPE is a popular choice for marine applications because of its resistance to saltwater and UV rays. It is commonly used in boat hulls, docks, and pontoons. The material's low friction and resistance to wear make it ideal for use in marine environments.

6. Transportation

HDPE sheets are also widely used in the transportation industry for applications such as truck bed liners, bumpers, and vehicle parts. The material's ability to withstand impact and its light weight make it an excellent choice for these applications.

Sourcing HDPE Sheets in Gujarat and Ahmedabad

If you're in need of high-quality HDPE sheets, sourcing them from reputable manufacturers and suppliers in Gujarat, specifically in Ahmedabad, is a great option. Gujarat is home to some of the leading HDPE sheet manufacturers in India, and Ahmedabad serves as a hub for many trusted HDPE sheet suppliers. These suppliers offer a wide range of HDPE products, catering to industries that require customized sheet sizes, colors, and thicknesses.

Working with experienced HDPE sheet manufacturers in Gujarat ensures that you receive high-quality products that meet the necessary industry standards. Whether you need HDPE sheets for construction, packaging, or agriculture, reliable suppliers can provide you with the right material tailored to your specific needs.

Additionally, there are several prominent HDPE sheets manufacturers in India who focus on delivering top-grade sheets for both domestic and international markets. By partnering with these manufacturers, you can access products that provide the ideal combination of strength, durability, and affordability.

How to Choose the Right HDPE Sheet Supplier?

When selecting an Hdpe sheets manufacturers in India, it is important to consider several factors:

Quality Assurance: Choose a supplier who follows industry standards and ensures quality control throughout the manufacturing process.

Customizability: Depending on your application, you may need HDPE sheets of specific sizes, thicknesses, or colors. Choose a supplier who can accommodate your customization needs.

Reputation: Look for suppliers who have a solid reputation in the market and a history of delivering products on time.

Pricing: Ensure that the pricing is competitive and aligns with the quality of the HDPE sheets you are purchasing.

Customer Support: Opt for a supplier who provides excellent customer support and is willing to offer technical assistance if needed.

Conclusion

HDPE sheets are a vital material in many industries due to their durability, strength, chemical resistance, and versatility. Whether you need them for packaging, construction, agriculture, or waste management, HDPE sheets offer a reliable solution for various applications. Sourcing HDPE sheets from reputable manufacturers and suppliers in Gujarat, such as those based in Ahmedabad, ensures that you get high-quality materials that meet your specific needs. By understanding the properties and uses of HDPE sheets, you can make informed decisions and choose the right product for your business or project.

Frequently Asked Questions (FAQs)

1. What is the difference between HDPE and LDPE sheets?

HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are both types of polyethylene plastic, but they differ in their molecular structure. HDPE sheets are more rigid, durable, and resistant to impact and chemicals compared to LDPE sheets, which are more flexible and softer. HDPE is ideal for applications requiring high strength, while LDPE is often used for flexible applications like plastic bags and films.

2. Can HDPE sheets be used for food contact applications?

Yes, HDPE sheets are safe for food contact applications. They are non-toxic, chemically resistant, and resistant to bacterial growth, making them suitable for food storage, packaging, and processing. However, it is important to ensure that the HDPE sheets meet the necessary food safety standards and certifications before use in food-related applications.

3. How should HDPE sheets be stored and maintained?

HDPE sheets should be stored in a cool, dry place away from direct sunlight and heat sources to prevent degradation. The sheets should be kept flat to avoid warping or bending. Regular cleaning with mild detergents and water is usually sufficient to maintain the surface. For industrial applications, it is important to follow the manufacturer’s recommendations for maintenance and care.