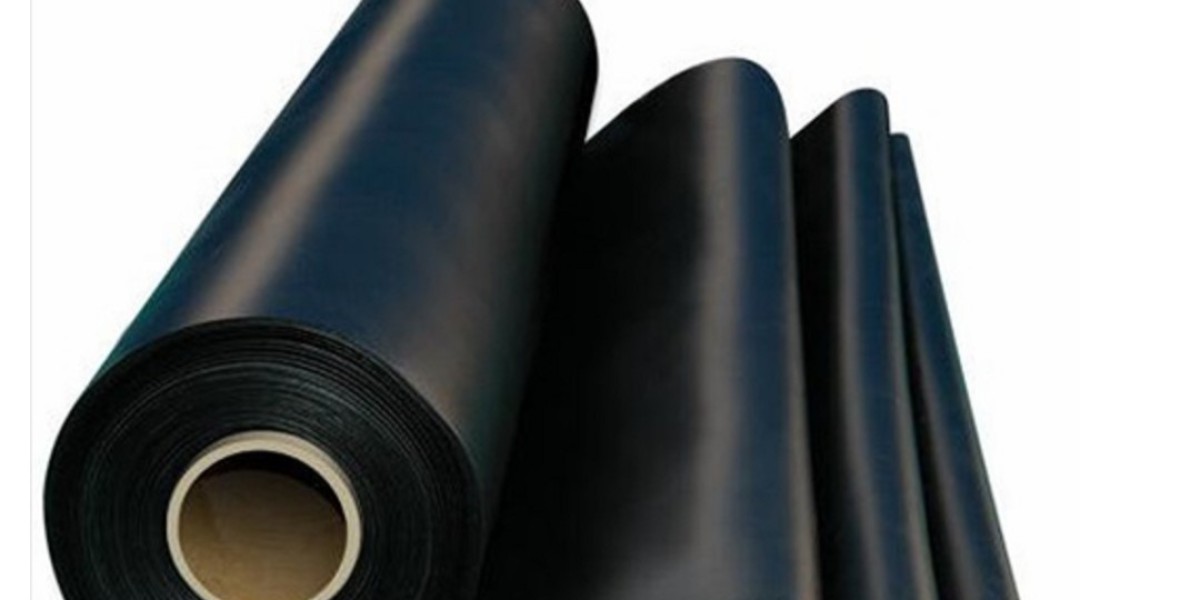

Unveiling the Polymeric Guardian: Engineered Barriers for a Sustainable Tomorrow

From safeguarding precious water resources to mitigating environmental contamination, the demand for reliable barriers is paramount. Enter the geomembrane sheet, a versatile material engineered to provide an impermeable layer, effectively creating a secure boundary against fluids and gases. These polymeric shields, meticulously crafted from materials like high-density polyethylene (HDPE), low-density polyethylene (LDPE), or polyvinyl chloride (PVC), are tailored to meet the exacting requirements of diverse applications. The precision with which these sheets are manufactured is vital, as they form the first line of defense against potential leaks and environmental hazards. The adaptability of geomembranes allows for their deployment in a multitude of settings, ranging from vast landfill liners to intricate water storage reservoirs. The ability to customize thickness, texture, and composition ensures that each project receives a solution precisely calibrated to its unique needs. The emphasis on durability and longevity underscores the crucial role these sheets play in ensuring the safety and sustainability of critical infrastructure.

The Symphony of Polymer Science: Material Innovation and Application Diversity

The science behind geomembranes is a testament to the advancements in polymer technology. The selection of materials is not arbitrary; it's a calculated decision based on the specific application and environmental conditions. HDPE, known for its exceptional chemical resistance and durability, is often preferred for demanding applications like mining and waste containment. LDPE, with its enhanced flexibility, finds its niche in applications requiring conformability, such as pond liners and irrigation canals. PVC, offering a balance of flexibility and strength, is utilized in applications like roofing and tunnel linings. The manufacturing process itself is a sophisticated dance of extrusion, calendering, and welding, ensuring the creation of a uniform and impermeable barrier. The integration of geotextiles, woven or non-woven fabrics, with geomembranes further enhances their performance by providing reinforcement, filtration, and protection against punctures. These composite systems are engineered to withstand the rigors of installation and long-term exposure, ensuring the integrity of the containment system. The dedication to material innovation by many Geotextiles And Geomembranes Manufacturers In India ensures that the industry constantly evolves to meet the ever-increasing demands for effective containment.

Navigating the Landscape: From Raw Material to Seamless Installation

The journey of a geomembrane sheet, from raw material to finished installation, is a testament to meticulous planning and execution. The process begins with the selection of high-quality polymer resins, which are then compounded with additives to enhance their properties, such as UV resistance and flexibility. The extrusion process, where the molten polymer is forced through a die, creates a continuous sheet of the desired thickness. Subsequent calendering and texturing processes further refine the sheet's surface characteristics. Quality control is paramount, with rigorous testing conducted at every stage to ensure compliance with industry standards and project specifications. The installation process itself is a critical phase, requiring skilled technicians and specialized equipment. Proper site preparation, including grading and compaction, is essential to create a stable foundation for the geomembrane. The sheets are then carefully deployed and welded together using thermal or chemical techniques, creating a seamless and impermeable barrier. The importance of proper installation cannot be overstated, as any defects or weaknesses can compromise the integrity of the entire containment system.

The Shield Against Environmental Intrusion: Safeguarding Water and Land

The environmental implications of geomembrane applications are profound. These engineered barriers play a crucial role in protecting groundwater resources from contamination by preventing the leaching of pollutants from landfills, mining operations, and industrial waste sites. In water management, geomembranes are used to line reservoirs, canals, and ponds, minimizing water loss due to seepage and evaporation. This ensures the efficient utilization of precious water resources, particularly in arid and semi-arid regions. The implementation of geomembranes in environmental remediation projects helps to contain and isolate contaminated soil and groundwater, facilitating the cleanup process and preventing the spread of pollutants. The role of Geomembrane Exporters In India is vital in disseminating this technology to international projects, aiding in global environmental protection efforts. The longevity of modern geomembranes, often exceeding several decades, ensures that these environmental benefits are sustained over the long term.

The Economic Imperative: Cost-Effectiveness and Long-Term Value

While the initial investment in geomembrane systems may seem substantial, the long-term economic benefits are undeniable. By preventing leaks and contamination, these barriers minimize the need for costly repairs and remediation efforts. In water management, the reduction of water loss translates to significant savings in water acquisition and treatment costs. In industrial applications, the prevention of chemical spills and leaks protects valuable assets and avoids costly downtime. The durability and longevity of geomembranes contribute to their cost-effectiveness, as they require minimal maintenance and replacement over their lifespan. Furthermore, the availability of diverse materials and installation techniques allows for the optimization of cost and performance, ensuring that each project receives a solution tailored to its specific budget and requirements. The competitive landscape of Geomembrane Sheet Manufacturers In India drives innovation and cost-efficiency, benefiting end-users across various sectors.

The Tapestry of Applications: Tailored Solutions for Diverse Sectors

The versatility of geomembranes extends across a wide range of industries and applications. In the mining sector, these sheets are used to line heap leach pads, tailings ponds, and evaporation ponds, preventing the contamination of soil and groundwater by hazardous chemicals. In the waste management sector, geomembranes are essential components of landfill liners, capping systems, and leachate collection systems, ensuring the safe disposal of solid waste. In the water management sector, they are used to line reservoirs, canals, irrigation ponds, and aquaculture facilities, optimizing water usage and preventing seepage. In the civil engineering sector, geomembranes are used in tunnel linings, dam linings, and foundation waterproofing, providing essential protection against water ingress and structural damage. In the environmental remediation sector, they are used to contain and isolate contaminated soil and groundwater, facilitating the cleanup process. The ability to customize geomembranes to meet the specific requirements of each application underscores their adaptability and effectiveness.

The Pursuit of Excellence: Quality Assurance and Technological Advancements

The pursuit of excellence in geomembrane manufacturing and installation is driven by a commitment to quality assurance and continuous technological advancement. Quality control measures are implemented at every stage of the manufacturing process, from raw material selection to finished product testing. Advanced testing techniques, such as tensile strength testing, puncture resistance testing, and permeability testing, ensure that the geomembranes meet the highest standards of performance and durability. The integration of advanced welding technologies, such as ultrasonic welding and hot wedge welding, ensures the creation of strong and reliable seams. The development of innovative materials and installation techniques further enhances the performance and cost-effectiveness of geomembrane systems. The ongoing research and development efforts in the industry are focused on improving the durability, flexibility, and chemical resistance of geomembranes, as well as developing more sustainable and environmentally friendly materials.

The Future of Containment: Sustainable Solutions for a Changing World

As the world faces increasing challenges related to environmental protection and resource management, the role of geomembranes will continue to grow. The demand for sustainable and cost-effective containment solutions will drive innovation and technological advancement in the industry. The development of biodegradable and recyclable geomembranes will contribute to a more circular economy. The integration of smart technologies, such as sensors and monitoring systems, will enable real-time monitoring of geomembrane performance, enhancing safety and efficiency. The expansion of geomembrane applications in emerging sectors, such as renewable energy and green infrastructure, will further solidify their importance in building a sustainable future. The collaborative efforts of manufacturers, engineers, and environmentalists will ensure that geomembranes continue to play a crucial role in safeguarding our planet and its resources.

Conclusion

Geomembrane sheets represent a critical innovation in engineering, providing essential containment solutions across diverse sectors. Their versatility, durability, and cost-effectiveness make them indispensable for environmental protection, water management, and infrastructure development. The commitment of manufacturers to quality assurance and technological advancement ensures that these polymeric barriers continue to meet the evolving needs of a changing world.

Frequently Asked Questions

What is the lifespan of a geomembrane sheet?

The lifespan of a geomembrane sheet depends on several factors, including the material type, environmental conditions, and installation quality. Generally, high-quality geomembranes can last for several decades, often exceeding fifty years, when properly installed and maintained.

Can geomembrane sheets be used in extreme weather conditions?

Yes, geomembrane sheets are designed to withstand a wide range of weather conditions, including extreme temperatures, UV radiation, and chemical exposure. Manufacturers offer geomembranes with specific properties to suit different climates and environmental challenges.

Are geomembrane sheets environmentally friendly?

Modern geomembrane sheets are designed to minimize environmental impact by preventing contamination and conserving resources. Many manufacturers are also exploring the development of biodegradable and recyclable geomembranes to further enhance their sustainability.

How are geomembrane sheets installed?

Geomembrane sheet installation involves site preparation, sheet deployment, and welding. Site preparation includes grading and compaction to create a stable foundation. The sheets are then carefully deployed and welded together using thermal or chemical techniques to create a seamless barrier. Skilled technicians and specialized equipment are essential for proper installation.