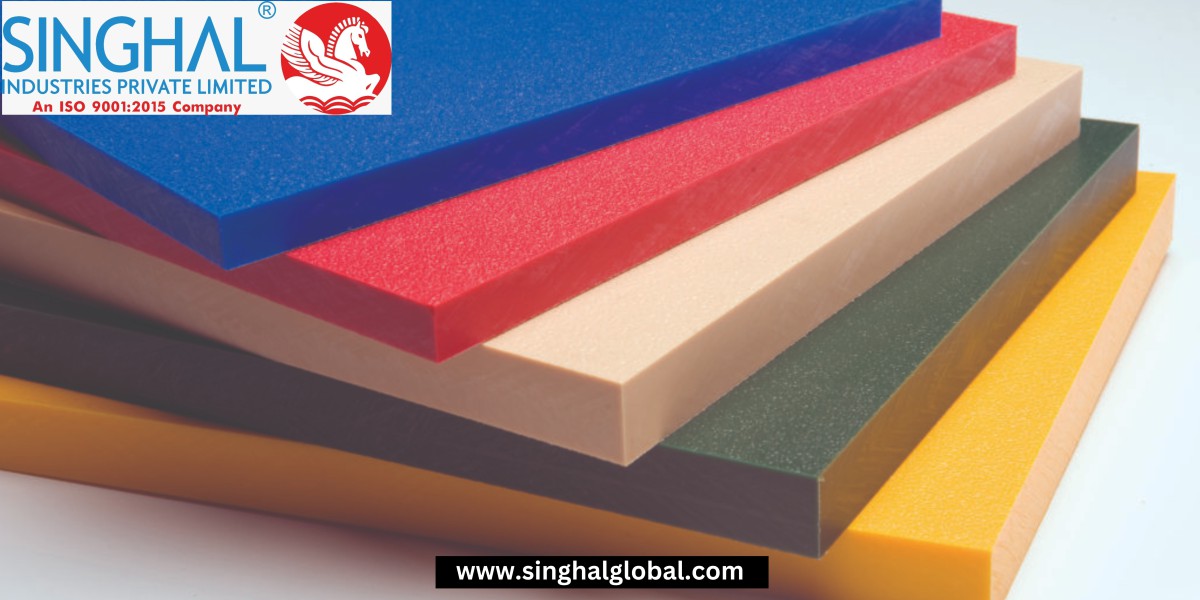

Unveiling the Versatility of Tailored Polypropylene Compositions

Polypropylene (PP) sheets, specifically, have carved a niche for themselves due to their remarkable adaptability and robust physical properties. This material, once relegated to packaging and basic consumer goods, is now being meticulously crafted to meet the stringent demands of diverse applications, from automotive interiors to chemical storage. The key to its transformation lies in the ability to manipulate its molecular structure and composition, resulting in sheets that exhibit tailored strength, flexibility, and resistance to environmental stressors. This customization is not merely a matter of adjusting thickness; it involves a deep understanding of polymer science and processing techniques. Imagine a sheet designed to withstand the corrosive onslaught of industrial acids, or another engineered to provide a lightweight yet rigid component for an aircraft interior. This is the reality of engineered polypropylene sheets, a testament to human ingenuity in material science.

The Foundation of Structural Soundness: Material Science in Action

The inherent properties of polypropylene, such as its chemical inertness and high melting point, serve as a solid foundation for further enhancement. However, it is the manipulation of these properties through advanced manufacturing processes that unlocks the true potential of the material. Techniques such as extrusion, calendering, and thermoforming are employed to create sheets with specific dimensions, textures, and performance characteristics. The inclusion of additives, such as fillers, stabilizers, and impact modifiers, further refines the material's properties, allowing for precise control over its strength, durability, and aesthetic appeal. For instance, the addition of glass fibers can significantly increase the tensile strength and stiffness of the sheet, making it suitable for structural applications. Similarly, UV stabilizers can protect the material from degradation caused by prolonged exposure to sunlight, extending its lifespan in outdoor environments. The ability to tailor the material's composition and processing parameters ensures that it can meet the unique requirements of each application, whether it be for electrical insulation, acoustic dampening, or thermal management.

Navigating the Industrial Landscape: Beyond

The demand for high-quality polypropylene sheets is driven by a multitude of industries, each with its own set of specifications and performance expectations. In India, a burgeoning manufacturing sector has led to the emergence of numerous Pp Sheets Suppliers In India, catering to both domestic and international markets. These suppliers play a crucial role in ensuring that industries have access to the materials they need to maintain production and innovation. The landscape is competitive, with suppliers vying to offer the most comprehensive range of products and services. Many are investing in state-of-the-art manufacturing facilities and quality control processes to meet the increasing demands of their customers. The ability to provide consistent quality, timely delivery, and competitive pricing is paramount in this dynamic market. Additionally, many companies are focusing on sustainability, offering recycled and recyclable polypropylene sheets to reduce their environmental footprint.

Regional Specialization: The Role of Pp Sheet Exporters

Within India, certain regions have emerged as hubs for specific industries, and the production of polypropylene sheets is no exception. Gujarat, with its strong industrial base and strategic location, has become a prominent center for Pp Sheet Exporters In Gujarat. These exporters leverage the region's manufacturing capabilities and logistical advantages to supply high-quality polypropylene sheets to customers around the world. The concentration of expertise and infrastructure in Gujarat has fostered a competitive environment, driving innovation and efficiency in the production and distribution of these materials. This regional specialization highlights the importance of geographical factors in the global supply chain, demonstrating how specific locations can become centers of excellence for particular industries. The ability to export high quality materials is a testament to the skill and investment in the region.

The Craft of Creation: The PP Sheets Manufacturer

At the heart of this industrial ecosystem are the PP Sheets Manufacturer In Gujarat, the companies that transform raw polypropylene resin into the finished products that are used in countless applications. These manufacturers employ a range of technologies and techniques to produce sheets that meet the specific requirements of their customers. From small-scale operations specializing in niche products to large-scale facilities producing high volumes of standard sheets, the manufacturing landscape is diverse and dynamic. These companies are constantly investing in research and development to improve their products and processes, seeking to enhance the performance, durability, and sustainability of their polypropylene sheets. The ability to innovate and adapt to changing market demands is crucial for success in this competitive industry. The dedication to quality and precision is evident in the products that these manufacturers produce.

From Automotive to Aerospace: The Breadth of Application

The versatility of engineered polypropylene sheets extends across a wide range of industries. In the automotive sector, these sheets are used for interior trim, door panels, and under-the-hood components, offering a lightweight and durable alternative to traditional materials. In the construction industry, they are used for roofing, cladding, and formwork, providing weather resistance and structural integrity. In the packaging industry, they are used for containers, trays, and protective packaging, ensuring the safe transport and storage of goods. In the medical field, they are used for medical devices, equipment housings, and sterile packaging, meeting stringent hygiene and safety standards. In the aerospace industry, they are used for lightweight interior components, contributing to fuel efficiency and passenger comfort. The applications are virtually limitless, demonstrating the adaptability of engineered polypropylene sheets to meet the diverse needs of modern industry.

Environmental Considerations: Sustainability and Innovation

As the world becomes increasingly aware of the environmental impact of plastics, the polypropylene sheet industry is responding with a focus on sustainability. Manufacturers are developing recycled polypropylene sheets, which reduce the reliance on virgin materials and minimize waste. They are also exploring the use of bio-based additives and biodegradable polymers to create more environmentally friendly products. Additionally, efforts are being made to improve the recyclability of polypropylene sheets, ensuring that they can be recovered and reused at the end of their life cycle. The emphasis on sustainability is not only driven by regulatory requirements but also by a growing demand from consumers and businesses for environmentally responsible products. Innovation in material science and manufacturing processes is playing a crucial role in achieving these sustainability goals.

The Future of Polypropylene: Continued Advancement and Expansion

The future of engineered polypropylene sheets is bright, with ongoing research and development paving the way for further advancements in material properties and manufacturing techniques. As industries continue to demand lightweight, durable, and sustainable materials, polypropylene sheets are poised to play an increasingly important role. The ability to tailor the material's properties to specific applications, combined with its inherent advantages such as chemical resistance and recyclability, makes it a versatile and valuable resource for a wide range of industries. The continued focus on innovation and sustainability will ensure that polypropylene sheets remain at the forefront of material science for years to come.

Conclusion

Engineered polypropylene sheets represent a remarkable achievement in material science, offering a versatile and robust solution for a multitude of applications. From the intricate processes of the PP Sheets Manufacturer In Gujarat to the global reach of Pp Sheet Exporters In Gujarat, and the reliable supply chains of Pp Sheets Suppliers In India, the industry continues to innovate and adapt. The ability to tailor the material's properties, combined with a growing emphasis on sustainability, ensures that polypropylene sheets will remain a vital component of modern manufacturing and construction.

Frequently Asked Questions

What are the key advantages of using engineered polypropylene sheets compared to other materials?

Engineered polypropylene sheets offer a combination of lightweight properties, chemical resistance, durability, and versatility. They can be tailored to meet specific application requirements, making them suitable for a wide range of industries.

How does the manufacturing process affect the properties of polypropylene sheets?

The manufacturing process, including extrusion, calendering, and thermoforming, plays a crucial role in determining the physical and mechanical properties of polypropylene sheets. Additives and processing parameters can be adjusted to achieve desired levels of strength, flexibility, and resistance.

What are the environmental benefits of using recycled polypropylene sheets?

Using recycled polypropylene sheets reduces the reliance on virgin materials, minimizes waste, and lowers the carbon footprint associated with manufacturing. It promotes a circular economy and contributes to a more sustainable future.

In what industries are engineered polypropylene sheets most commonly used?

Engineered polypropylene sheets are commonly used in the automotive, construction, packaging, medical, and aerospace industries, among others. Their versatility and adaptability make them suitable for a wide range of applications.