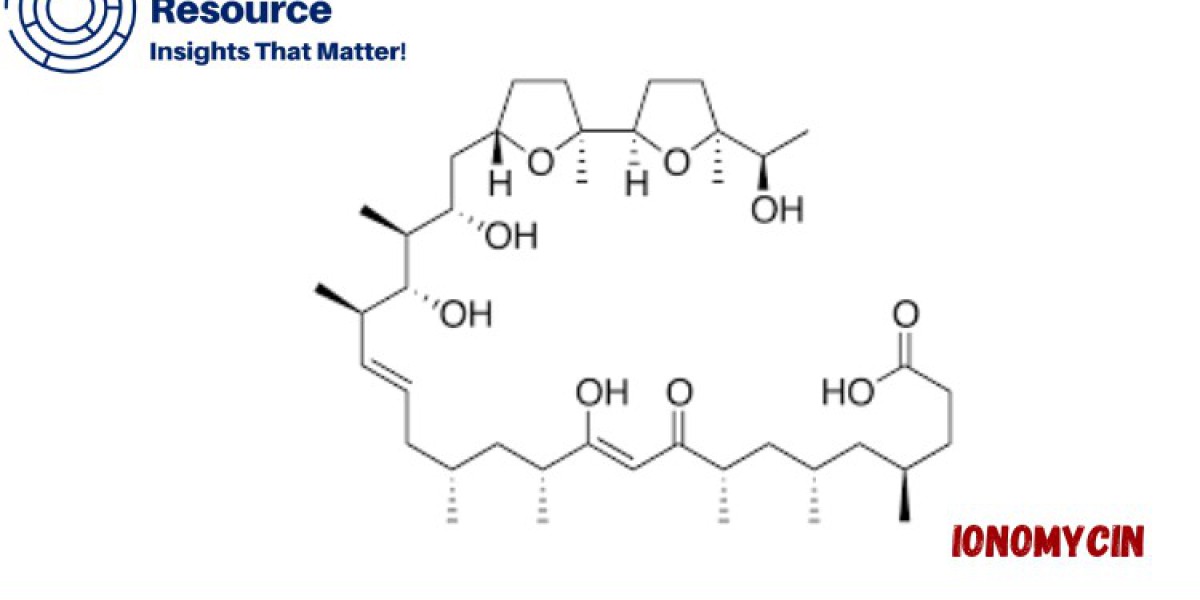

Ionomycin, a unique ionophore antibiotic, is primarily used to increase intracellular calcium levels and is an essential tool in research, especially in cell biology, immunology, and various biotechnological applications. Given its significance, understanding the Ionomycin production cost is crucial for research facilities, pharmaceutical companies, and suppliers to ensure cost-effectiveness and operational efficiency. Procurement Resource offers comprehensive Ionomycin Production Cost Reports, providing insights into each component of production expenses and delivering data-driven strategies for companies aiming to stay competitive.

Request a Free Sample for Ionomycin Production Cost Reports – https://www.procurementresource.com/production-cost-report-store/ionomycin/request-sample

Why Ionomycin is Important

Ionomycin is widely used in laboratory and pharmaceutical settings, where it acts as a calcium ion carrier, facilitating calcium flux into cells. This characteristic makes it invaluable in research areas such as studying calcium signaling, cell activation, and immune responses. It also has various applications in pharmaceuticals, as calcium plays a crucial role in physiological and biochemical processes. Due to its specialized function, ionomycin is a high-demand product in scientific research and healthcare, further emphasizing the need to optimize production costs.

Request a Free Sample for Ionomycin Production Cost Reports

If you’re interested in a more in-depth understanding of ionomycin production costs, we encourage you to request a free sample of our comprehensive Ionomycin Production Cost Report.

Key Factors Behind Ionomycin Production Costs

The production of ionomycin involves several critical cost elements, including raw materials, specialized labor, equipment, regulatory compliance, and facility maintenance. Here’s a breakdown of the main factors impacting ionomycin production costs:

Read the Full Report – https://www.procurementresource.com/production-cost-report-store/ionomycin

Raw Material Costs

Ionomycin production begins with specific raw materials, including microbial cultures and other organic compounds essential for antibiotic synthesis. The cost of raw materials can vary significantly based on purity standards, supplier location, and fluctuations in supply. Additionally, sourcing high-quality raw materials is crucial for meeting industry standards, particularly for pharmaceutical applications, making this a significant part of the production cost.

Labor and Operational Costs

Ionomycin production requires skilled labor and technical expertise, given the complexity of the biosynthetic processes involved. Experienced biotechnologists, chemists, and laboratory personnel play a crucial role in maintaining production efficiency and ensuring product quality. Labor costs may vary depending on regional wage levels and labor availability. Additionally, maintaining cleanroom standards and lab safety adds to operational costs, as stringent conditions must be adhered to throughout production to meet regulatory standards.

Specialized Equipment and Facility Costs

Producing ionomycin requires specialized equipment for microbial fermentation, extraction, and purification processes. High-performance equipment, such as bioreactors, chromatography systems, and analytical instruments, is used to ensure product quality and purity. Facility costs include expenses for equipment maintenance, periodic calibration, and infrastructure that complies with industry standards for pharmaceuticals and biotechnology products.

Energy and Utility Costs

The production process for ionomycin is energy-intensive, as it involves maintaining specific conditions for microbial culture growth and conducting purification procedures. Energy expenses include electricity for equipment operation, heating, ventilation, air conditioning (HVAC) systems for maintaining cleanroom environments, and water for cooling and sterilization. Energy costs can fluctuate depending on regional rates, utility demand, and market conditions, impacting overall production costs.

Regulatory and Quality Control Costs

Given ionomycin’s role in research and pharmaceuticals, adherence to strict regulatory standards is essential. Compliance with industry-specific standards, such as Good Manufacturing Practices (GMP), and ensuring quality control at every production stage add to the production costs. Regular quality checks, validation tests, and documentation are required to ensure product safety and efficacy. Additionally, regulatory compliance involves costs related to audits, certifications, and periodic inspections by health authorities.

How Procurement Resource’s Ionomycin Production Cost Reports Can Help

At Procurement Resource, we provide Ionomycin Production Cost Reports that break down each component of the production process into actionable insights. Our reports deliver a clear view of the cost structure, helping businesses identify areas for cost savings, streamline operations, and implement data-driven decisions. Here’s what our reports offer:

Detailed Cost Breakdown: From raw materials and labor to equipment, energy, and regulatory compliance, our reports offer a comprehensive breakdown of all factors that influence ionomycin production costs.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/ionomycin/ask-an-analyst

Real-Time Data: Our reports provide current data and forecasts on market conditions that impact ionomycin production costs, helping companies stay updated with the latest trends in the biotech and pharmaceutical sectors.

Price Trends and Analysis: Our reports include in-depth analyses of pricing trends, allowing stakeholders to understand market movements and plan for potential cost fluctuations in ionomycin production. This information is critical for budgeting, procurement planning, and long-term investment decisions.

Benchmarking and Comparison: Our reports allow companies to compare their production costs with industry standards, identifying opportunities to reduce expenses or improve efficiency.

Procurement Insights: We offer practical procurement strategies to help businesses manage their ionomycin supply chain effectively, optimize costs, and secure a competitive edge.

Stay Ahead of Market Trends with Procurement Resource

By partnering with Procurement Resource, you gain access to comprehensive insights that empower your business to stay at the forefront of the ionomycin market. Our Ionomycin Production Cost Reports simplify the procurement process, support data-driven decision-making, and enhance supply chain management.

Our team of expert analysts and researchers examines market drivers and cost factors to provide clients with detailed, actionable data. Whether you’re looking to control production costs, meet regulatory standards, or improve operational efficiency, our customizable reports can be tailored to your unique needs.

Request Your Free Sample Report Today

If you're ready to gain control of your ionomycin production process, we invite you to request a free sample report from Procurement Resource. Our insights provide you with the tools to understand the full cost dynamics of ionomycin production, improve efficiency, and stay competitive in the biotechnology and pharmaceutical markets.

Request Your Free Sample – https://www.procurementresource.com/production-cost-report-store/ionomycin/request-sample

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: [email protected]

Toll-Free Numbers:

USA copyright: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA