PLA (Polylactic Acid) straws have become a popular alternative to traditional plastic straws due to their biodegradability and environmentally friendly nature. A PLA Straw Machine production line is designed to manufacture these eco-friendly straws from raw PLA material, offering a sustainable solution to single-use plastic products.

A complete PLA straw production line is a production line for producing PLA straws, which consists of a PLA straw extruder, water tank, cutting machine, pipe sorting machine, packaging machine and other mechanical equipment. The following is a detailed introduction of these straw machinery and equipment.

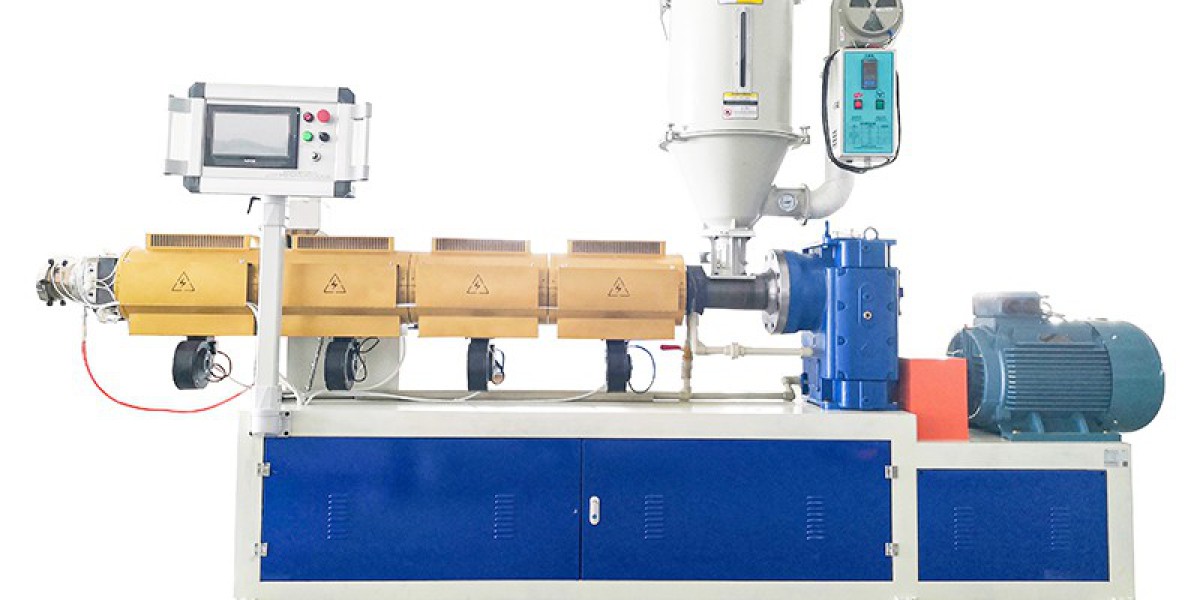

PLA Straw Extruder

The PLA straw extruder is the heart of the production line, featuring an advanced pineapple pin + BM separation screw design. It is equipped with a servo motor and direct connection structure, enabling the production of up to 1,800 straws per minute. The PLA material is melted and shaped into straws through the extruder, forming the initial straw shape.

Water Tank

After extrusion, the PLA straws are cooled in a water tank. The length of the water tank can be customized based on production requirements. This step ensures that the straws solidify and maintain their shape.

Straw Cutting Machine

Once the straws have cooled, they are fed into a cutting machine. This machine precisely cuts the straws to the desired length, ensuring smooth and clean edges. The cutting process is essential for producing uniform and aesthetically pleasing straws.

Straw Arranging Machine and Conveyor

The straw arranging machine and conveyor work together to collect, organize, and transport the straws. The arranging machine aligns the straws neatly, while the conveyor moves them to the next stage of the production process. This ensures a smooth flow of materials through the production line.

Single Straw Packaging Machine

The single straw packaging machine automates the process of packaging individual straws. This includes printing, filling, sealing, and cutting. The result is neatly packaged individual straws, ready for distribution. The packaging machine not only improves efficiency but also enhances product presentation.

Secondary Multi-Straw Packaging Machine

For bulk packaging, the secondary multi-straw packaging machine is used. This machine can seal, package, and cut multiple straws at once, producing tightly packed bundles of PLA straws. The three-side sealing and cutting process ensures that the packaging is compact and visually appealing.

Production Process Overview

The entire PLA straw production process begins with the extrusion of PLA material into straw shapes using the advanced extruder. After the straws are formed, they are cooled in the water tank, cut to size by the cutting machine, and then organized by the straw arranging machine. The straws are then packaged individually by the single straw packaging machine or in bulk by the secondary multi-straw packaging machine, depending on customer requirements.

Conclusion

In summary, a PLA straw machine production line includes various interconnected machines such as the extruder, water tank, cutting machine, straw arranging machine, conveyor, single straw packaging machine, and secondary multi-straw packaging machine. These machines work together seamlessly to complete the entire production process, from raw material processing to final packaging.

As the only supplier in China offering a full range of straw production machinery, we provide fully automated straw production lines to help you achieve high-quality straw manufacturing with complete automation. No matter what challenges you face at any stage of straw production, we are here to provide solutions for you. Visit our website for more details https://www.marrow-ll.com/